Repairing a Cracked Chimney Flue: Ensuring Safety and Proper Function

Addressing a cracked chimney flue is crucial to maintain the structural integrity and safety of your chimney system. Here’s what the repair process entails:

-

Assessment: A professional chimney technician will conduct a thorough inspection to assess the extent of the crack and determine the best repair approach.

-

Flue Liner Replacement: If the crack is severe, replacing the flue liner might be necessary. This involves removing the damaged liner and installing a new one made from suitable materials like stainless steel or ceramic.

-

Sealing Cracks: Minor cracks can often be sealed using specialized refractory sealants. These sealants can withstand high temperatures and effectively seal off small cracks to prevent moisture entry and further deterioration.

-

Resurfacing: In some cases, resurfacing the interior of the flue with a heat-resistant coating might be recommended. This reinforces the flue’s integrity and provides added protection.

-

Professional Expertise: It’s crucial to entrust flue repairs to certified chimney professionals who have the expertise and tools to ensure a proper repair. DIY repairs can lead to inadequate fixes and potential safety hazards.

-

Preventive Measures: Regular chimney inspections and maintenance can help detect cracks early, allowing for prompt repairs. Preventing water infiltration through proper chimney caps and maintenance can also reduce the risk of future cracking.

Remember that a cracked chimney flue can compromise the safety of your home and affect the efficiency of your fireplace. Consulting with professionals and addressing the issue promptly ensures the continued functionality and safety of your chimney system.

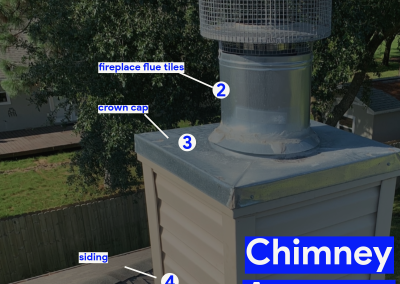

Understanding Chimney Anatomy and Components: Exploring the Key Elements

Comprehending the anatomy and components of a chimney is essential for maintaining its efficiency, safety, and proper functionality. Here’s a breakdown of its key elements:

-

Chimney Cap: The chimney cap sits at the top, protecting the flue from rain, debris, and animals. It also helps prevent downdrafts and sparks from escaping.

-

Flue Liner: This protective layer lines the interior of the chimney. It prevents heat transfer to surrounding materials, contains combustion byproducts, and prevents moisture from damaging the chimney.

-

Smoke Chamber: Located above the firebox, the smoke chamber funnels smoke from the firebox to the flue. Its design is crucial for efficient smoke and gas flow.

-

Damper: The damper is a movable plate that regulates airflow. It helps control the intensity of the fire and prevents heat loss when the fireplace is not in use.

-

Firebox: The firebox is where the actual combustion occurs. It’s constructed with fire-resistant materials to withstand high temperatures.

-

Hearth: The hearth is the non-combustible area in front of the firebox. It serves as a safety barrier and can be made from various materials like stone, brick, or tile.

-

Ash Pit: This compartment collects ash and debris that fall through the fire grate. Regular cleaning of the ash pit is essential to maintain proper airflow.

-

Smoke Shelf: Situated at the bottom of the smoke chamber, the smoke shelf prevents downdrafts and debris from falling directly into the firebox.

-

Lintel: The lintel is a horizontal support that spans the top of the firebox opening. It provides structural stability to the chimney.

-

Crown: The chimney crown is a concrete or mortar layer that covers the top of the chimney. It helps prevent water from seeping into the chimney structure.

-

Masonry: The masonry, which includes bricks, stones, and mortar, forms the chimney’s exterior. Proper maintenance of masonry prevents water damage and deterioration.

Understanding these components is fundamental to ensure proper maintenance, detect issues, and address repairs promptly. Regular inspections by professionals are essential to maintain a safe and efficient chimney system.